GEM Complex Event Processing for Industry 4.0 Applications

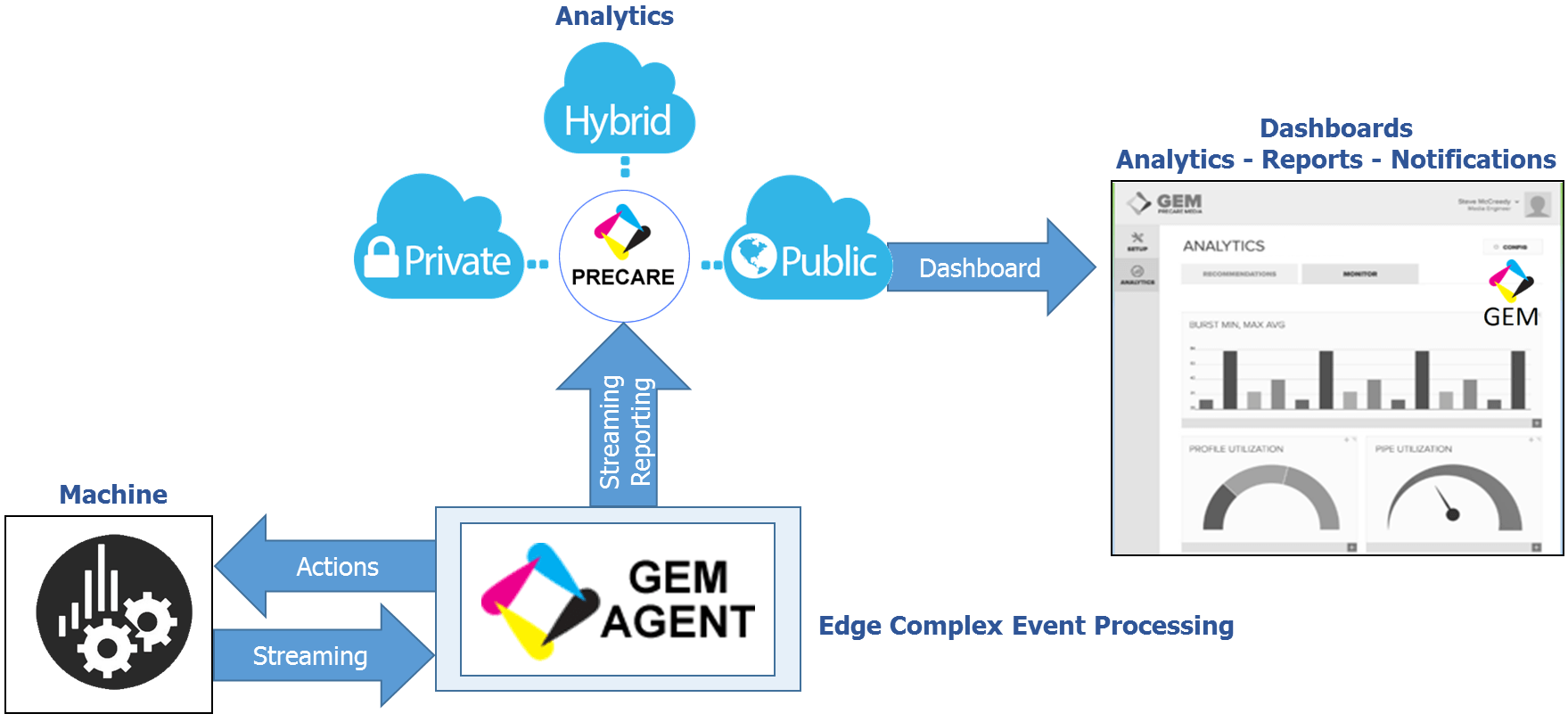

The GEM PRECARE platform enables manufacturers to seamlessly make the transition to Industry 4.0, while keeping their investments in legacy machines; thus, being able to tap into the potential of real-time access to sensor data in order to improve efficiency, productivity and quality.

Real-time access to process data is made possible through the deployment of sensors and is crucial in process control and monitoring. Complex event processing, or CEP in short, at the edge of the cloud or at the machine itself requires hardware platforms with adequate processing power. GEM Precare supports edge processing of sensor data through the use of powerful GEM Agents. These agents support a wide variety of embedded hardware platforms based on ARM, MIPS and x86 embedded processors, as well as embedded OSes, such as various Linux flavors and real-time OSes. Furthermore, GEM Agents can also take advantage of programmable hardware, such as FPGAs, and accelerators, such as DSPs.

Another important benefit derived from real-time access to machine performance data is the ability to perform data analytics and to apply machine learning techniques to spot trends which can predict when to schedule maintenance. The benefit of predictive maintenance over planned maintenance is that the former reduces the amount of down-time of the machine, since it’s no longer being serviced at regular intervals regardless of the actual performance or condition of the machine, but only in case of reaching a preset maximum tolerance level, the timing of which can be predicted from trends over time in the data patterns of the machine.Thus, predictive maintenance increases overall equipment effectiveness, or OEE in short.

Motors used in machines and production processes are very common and the ability to monitor them in real-time is understandably of crucial importance. GEM has developed an end-to-end motor control and monitoring solution in collaboration with Intel and B&R Automation, that takes advantage of the versatile and powerful GEM Agents for CEP at the edge and the GEM Precare cloud platform for monitoring and predictive maintenance. The process diagram shown below depicts a flow control application example. Control of a pump controls the flow rate in a pipe, and a safety valve prevents overpressure inside the pip

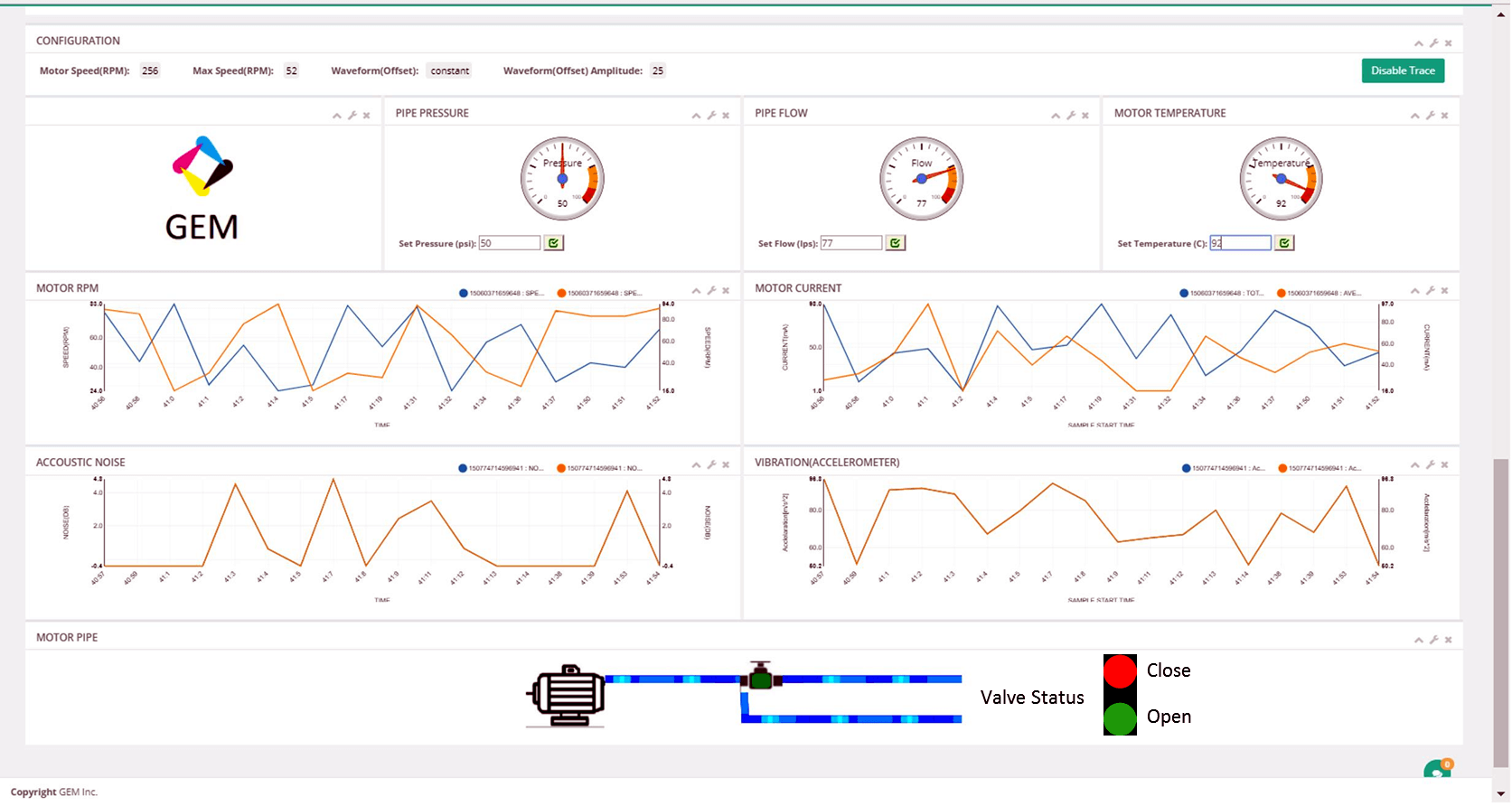

The critical parameters that are controlled in this setup for the pipe are pressure, flow rate and flow path. The latter is controlled by a safety valve. For the pump these critical parameters are the pump’s motor temperature, RPM, current consumption, vibration and acoustic noise. Pipe pressure and flow rate are directly influenced by the RPM of the pump’s motor.

The system diagram for the monitoring of these parameters and controlling the motor and the safety valve is shown below.

A PCIe add-on card with an Intel Cyclone V SoC FPGA performs the actual motor control and sensing of motor current consumption, RPM and temperature. An X20CP PLC from B&R Automation monitors vibration and acoustic noise. An Intel Skylake x86-based computer runs the GEM Agent and provides the communication link over Ethernet with the GEM PRECARE platform running in the cloud. This computer functions at the same time as a gateway and communicates over Ethernet with the B&R Automation X20CP PLC.

A GEM Agent runs on the embedded ARM processor in the the Cyclone V FPGA, collecting the motor parameters. An other GEM Agent runs in OPC-UA client mode on the computer based on the Intel Skylake CPU. This agent collects the sensor data coming from the GEM Agent on the FPGA and from the B&R Automation X20CP PLC. This PLC runs in OPC-UA server mode. The OPC-UA client/server model adds the benefit that all communication between the different entities in the network conform to open industry standards.

The GEM PRECARE dashboard is shown below. The dashboard uses gauge widgets to present the pipe pressure and flow, as well as the pump’s motor temperature in real-time. Pump motor RPM and current consumption, as well as the pump motor vibration and acoustic noise are shown in real-time in graph widgets. The safety valve status is displayed by a “traffic light” widget, which switches on the corresponding light when the valve is open or closed.

The complex event processing (CEP) rules implemented for the control of the motor are as follows:

- If motor temperature exceeds temperature threshold level 1 and motor RPM exceeds RPM threshold, then the GEM Agent will start reducing the RPM; the GEM PRECARE platform will display a high temperature alarm and the action undertaken by the GEM Agent to prevent a catastrophic failure, until the temperature has dropped again below temperature threshold level 1.

- If motor temperature exceeds temperature threshold level 2 and motor RPM exceed RPM threshold, then the GEM Agent will immediately reduce the motor RPM to zero and simultaneously open the safety valve to relieve pressure in the pipe; the GEM PRECARE platform will display a catastrophic high temperature alarm and the action undertaken by the GEM Agent, until the temperature has dropped again below temperature threshold level 1.

- If motor RPM exceeds RPM threshold and pipe pressure exceeds pressure threshold 1, then the GEM Agent will start reducing the RPM; the GEM PRECARE platform will display a high pressure alarm and the action undertaken by the GEM Agent to prevent a catastrophic failure, until the pressure has dropped again below pressure threshold level 1.

- If motor RPM exceeds RPM threshold and pipe pressure exceeds pressure threshold 2, then the GEM Agent will immediately reduce the motor RPM to zero; the GEM PRECARE platform will display a catastrophic high pressure alarm and the action undertaken by the GEM Agent, until the pressure has dropped again below pressure threshold level 1.

The above illustrates the power and advantage of the GEM Agent in order to execute edge CEP for time-critical monitoring and control. This allows the GEM Agent to take immediate action and do so autonomously rather than under control of GEM PRECARE.

The same motor control instance can be repeated many times in a large plant with multiple motors and safety valves, such as in a distillery for instance. Each instance is connected via the GEM Agents to the GEM PRECARE platform. Whereas the GEM Agents perform control and CEP at the edge, the GEM PRECARE platform is fed data from all motor control instances in the plant, allowing it to present a dashboard for each instance, calculate OEE, MTBF and MTBA for each instance as well as for the entire plant, and analyze the monitored signals to create predictive maintenance models.

Contact Us