Transition to Industry 4.0 with GEM PRECARE

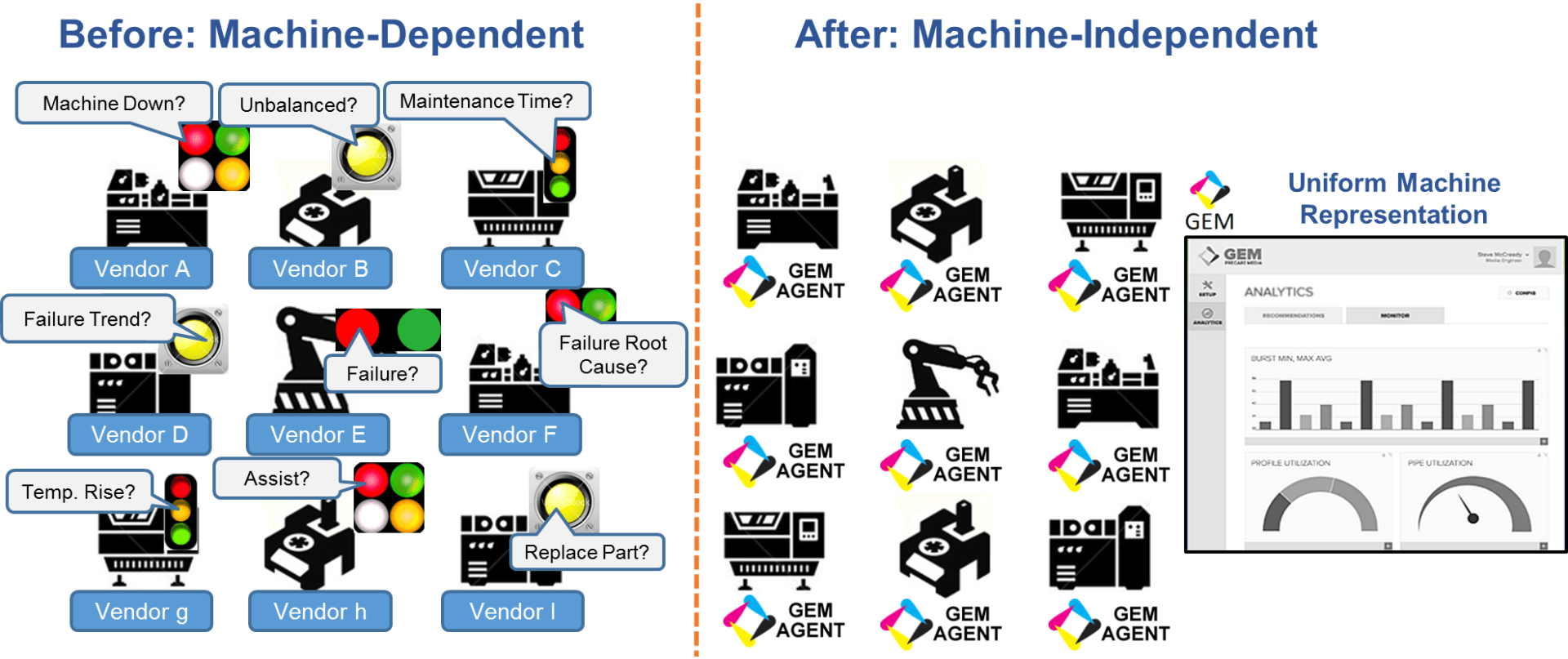

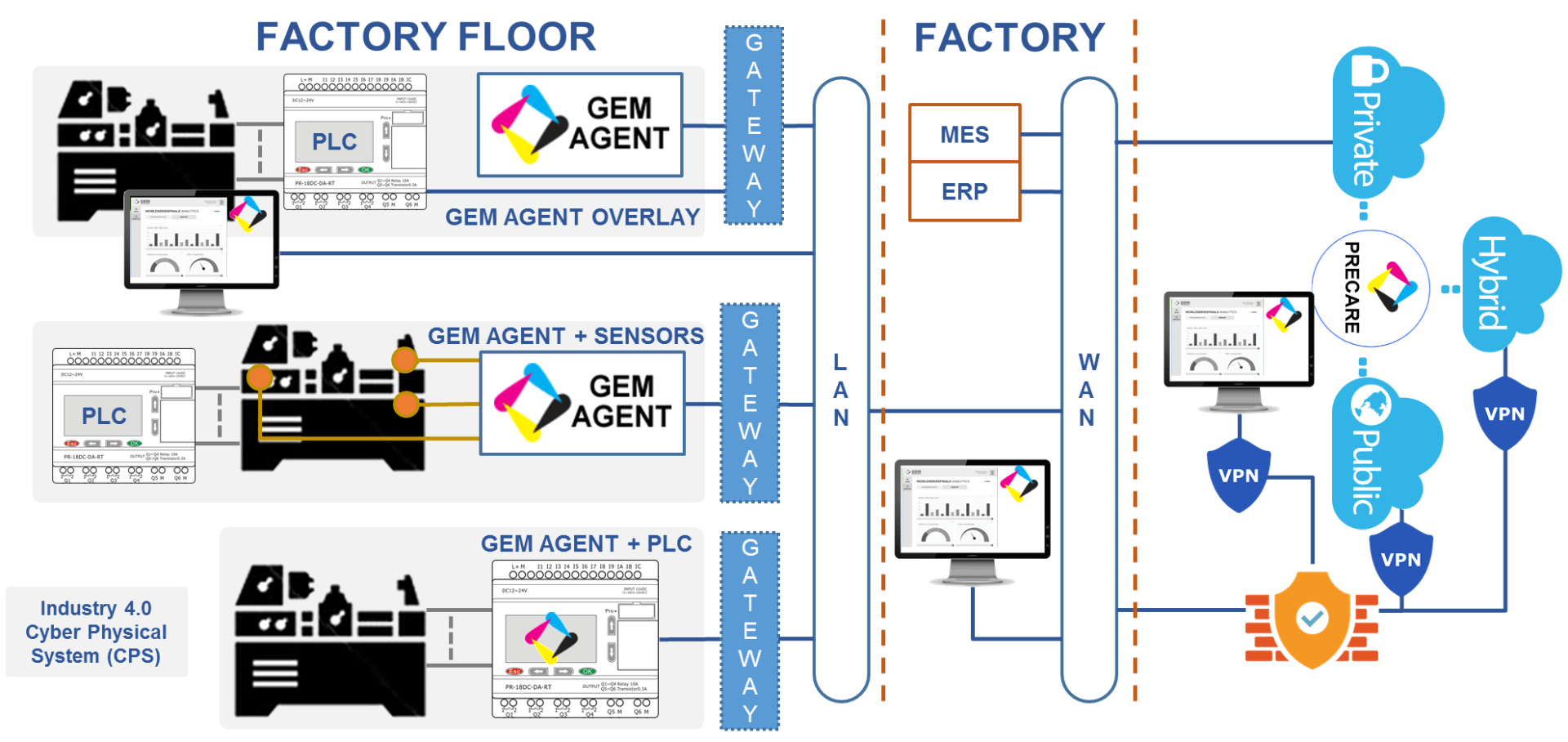

The GEM PRECARE platform offers manufacturers the ability to easily access critical operational data in real-time from the production floor. GEM PRECARE can be used in a private, public or hybrid cloud setting and combines powerful, best-in-manufacturing edge processing, analytics and predictive and preventive maintenance capabilities with versatile and user-friendly dashboards. These give operators a unified presentation across all machines instead of having to deal with different man-machine interfaces for each machine. GEM PRECARE’s machine learning, analytics and predictive and preventive maintenance features help manufacturers drastically reduce machine downtime, hence positively affecting quality control, productivity and revenues.

Unified Interface for all Machines Across the Factory Floor

Digital Twins (Cyber Physical Systems)

GEM agents provide operators with a digital twin of their machines on the production floor. These are equivalent to cyber physical systems in Industry 4.0 parlance. GEM agents interface upstream with the GEM PRECARE platform through Ethernet and downstream with production floor machinery. The downstream interface can be over different physical connections, not just Ethernet, but for instance UART or any other serial or parallel connection. Agent downstream connections can be with a machine, a PLC which controls the machine, or with physical sensors. Any combination of these is supported as well. GEM agents define sensors as any port they receive factory data from. This can be for instance from a physical sensor, but also from a data file on a PLC or a networked data store on the factory floor.

Hardware, OS and Protocol Agnostic

GEM agents support a wide choice of different hardware platforms, including PCs, mobile devices, custom hardware, CPUs, FPGAs, etc., Linux and Microsoft Windows operating systems, as well as a large number of different protocols, legacy and new, such as RS-485/232,IEEE 1284, SCADA, SECS/GEM, OPC-UA, MQTT, etc. This means that GEM is able to support any production machine in use, legacy or new. This is a huge benefit to manufacturers, since they can extend the life of their legacy machines as they transition to Industry 4.0 compliant manufacturing systems. In addition, GEM agent hardware platforms support high-speed data acquisition and enhanced, complex processing at the edge, including sensor signal processing, machine learning and complex event processing, hence rising to the challenge of meeting the most demanding customer requirements.

Contact Us