generators

Reducing OPEX and Increasing Customer Satisfaction for Industrial and Commercial Use Power Generators

With GEM PRECARE IIoT Platform for OEE and Predictive Maintenance

Abstract

Customers of industrial and commercial use power generators place high expectations on the quality, performance and availability of these systems. They expect them to perform reliably at a moment’s notice when needed, with little or no interruption. The same OEE (overall equipment effectiveness) and predictive maintenance principles used in the manufacturing industry apply to industrial and commercial use power generators. With the GEM Precare Platform, power generator OEMs and their service partners can achieve significant reductions in operational expenses and see significant increases in customer satisfaction.

Negative Impacts on OPEX and Customer Satisfaction

Industrial and commercial use power generators are complex systems, which are required to operate reliably without interruption and to be available whenever the need arises for backup power. Like with any complex system any number of things can go wrong and will go wrong, no matter the level of planning and preparation. The challenge is therefore to minimize the financial, operational and psychological cost of any malfunction or suboptimal functioning of the system. The following equipment related events negatively impact operational cost and customer satisfaction:

- Equipment breakdown.

- Equipment downtime, regardless of maintenance, repair, out of fuel or other reasons.

- Reduced power output.

What if you could minimize the probability of any of these events and hence reap the fruits of reduced OpEx and increased customer satisfaction?

The GEM PRECARE Solution

GEM Precare uses the power of data, analytics and machine learning to mitigate and minimize the impact of equipment related adverse events through the following:

- Predictive maintenance. Avoid costly unscheduled and unnecessary scheduled downtime. Instead determine when precisely to schedule maintenance.

- Catastrophic failure prevention. Avoid costly catastrophic failures, for instance by early detection of abnormal vibrations in rotating parts.

- Maintenance/repair time reduction. Avoid expensive maintenance/repair crew hours with prior knowledge of the kind of maintenance or repair and which spare parts are needed.

- Truck-roll reduction. Avoid unnecessary truck rolls by minimizing planned and unplanned downtime while simultaneously having sufficient information upfront to determine what needs maintenance and/or repair.

- Overall Equipment Effectiveness & customer satisfaction optimization. Maximize OEE and customer satisfaction by eliminating unnecessary and unplanned downtime by keeping any downtime at a minimum and by keeping customer premise equipment running at optimal performance.

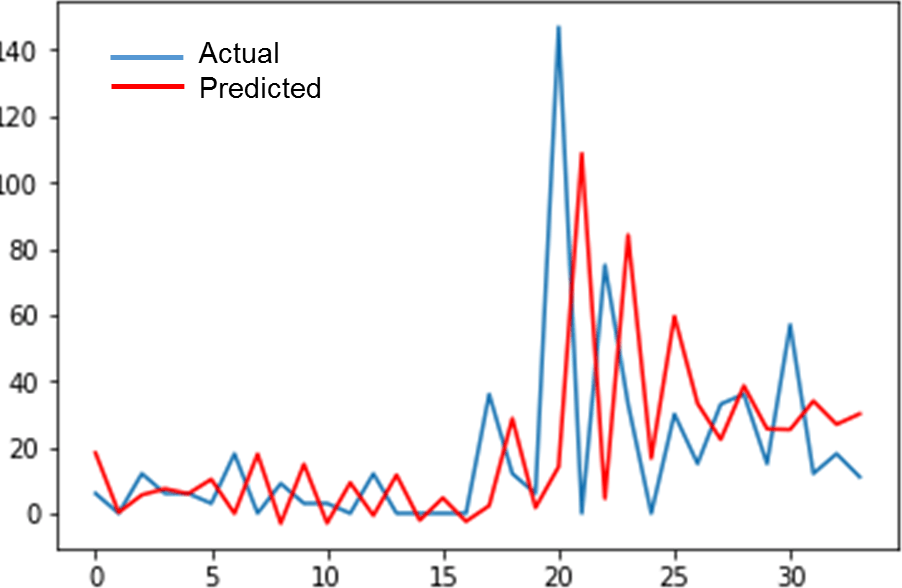

Predictive Maintenance

GEM Precare collects failure data and uses machine learning to construct models that can accurately predict when a failure has the highest probability of happening. An example is shown below.

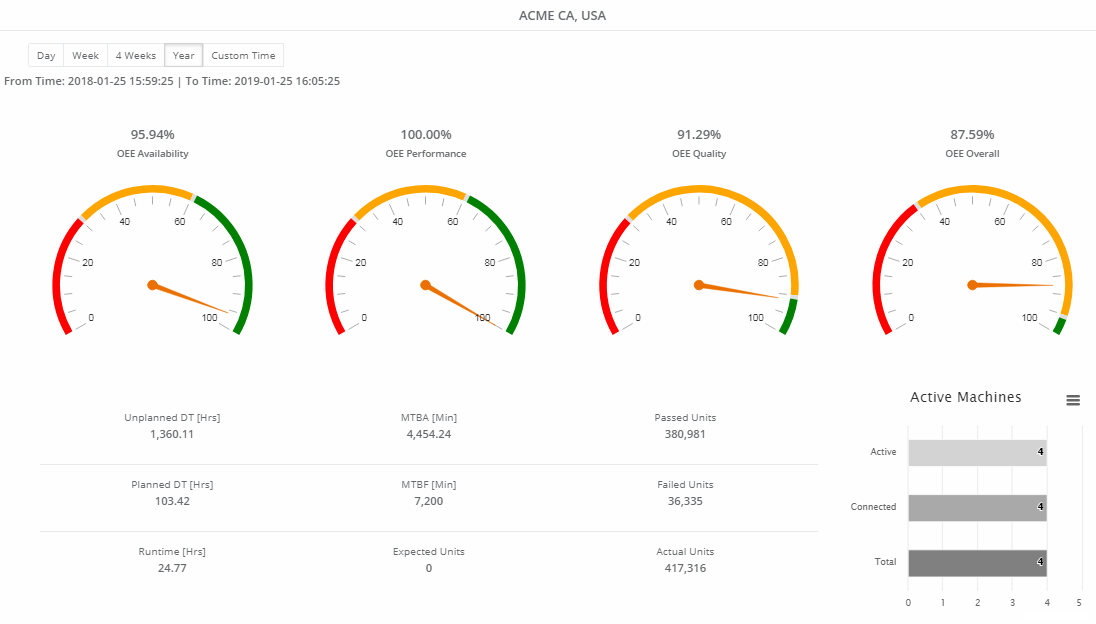

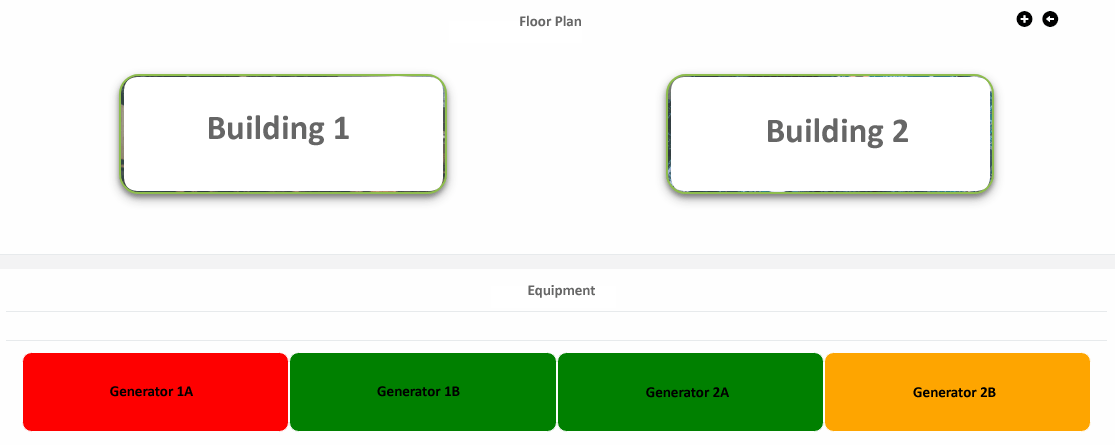

OEE जिस तरह उपकरण उपलब्धता को अनुकूलित करने और अनावश्यक शेड्यूल्ड डाउनटाइम को खत्म करने के लिए भविष्य कहनेवाला रखरखाव महत्वपूर्ण है, उसी तरह OEE भी है। OEE एक महत्वपूर्ण KPI और उपकरण है जो उन घटनाओं और कारकों की खोज करता है जो उपकरण प्रभावशीलता और ग्राहकों की संतुष्टि पर प्रतिकूल प्रभाव डालते हैं। OEE को OEE = उपलब्धता x प्रदर्शन x गुणवत्ता के रूप में व्यक्त किया जाता है। इनमें से प्रत्येक घटक को निम्नानुसार मापा जाता है: उपलब्धता; एक निर्दिष्ट समय अंतराल में उपकरण द्वारा बिजली पैदा करने में लगने वाले समय के संदर्भ में मापा जाता है। प्रदर्शन; उस दर के संदर्भ में मापा जाता है जिस पर उपकरण बिजली का उत्पादन कर रहा है, यानी, किलोवाट घंटे में मापा जाता है, या प्रति घंटे उत्पादित ऊर्जा की मात्रा। गुणवत्ता; एक निर्दिष्ट समय अंतराल के भीतर उत्पादित किलोवाट में कुल शक्ति के संदर्भ में मापा जाता है। इसमें निर्दिष्ट अंतराल के भीतर अनुभव किया गया कोई भी डाउन टाइम शामिल है। GEM Precare न केवल उपलब्धता, प्रदर्शन, गुणवत्ता और OEE की गणना करने के लिए आवश्यक सभी डेटा एकत्र करता है, बल्कि कम OEE के कारण (कारणों) के बारे में बताता है। एक स्थापना के लिए एक उदाहरण नीचे दिखाया गया है जिसमें दो भवन हैं, प्रत्येक में दो बिजली जनरेटर हैं। GEM प्रीकेयर रूल इंजन एक या अधिक मॉनिटर किए गए संकेतों द्वारा एक साथ मिलने वाली एक या अधिक शर्तों के परिणामस्वरूप क्रियाओं को स्वचालित रूप से निष्पादित करने की अनुमति देता है। शीर्ष स्तर पर OEE KPI को दोनों भवनों के लिए दिखाया जाता है, अर्थात, दोनों जनरेटरों को मिलाकर। प्रत्येक OEE KPI विवरण को भी सूचीबद्ध करता है। उदाहरण के लिए, उपलब्धता KPI के लिए अनियोजित, नियोजित और कुल रन टाइम के घंटे दिखाए जाते हैं।

Since the number of unplanned downtime hours is relatively high over the 1 year period selected, the next step is to find out which generator is experiencing high levels of unplanned downtime. Examining the floor plan shows that generator 1A at building 1 is in the red zone currently, experiencing a failure. Generators 1B and 2A are operating normally and generator 2B is experiencing some form of assistive action.

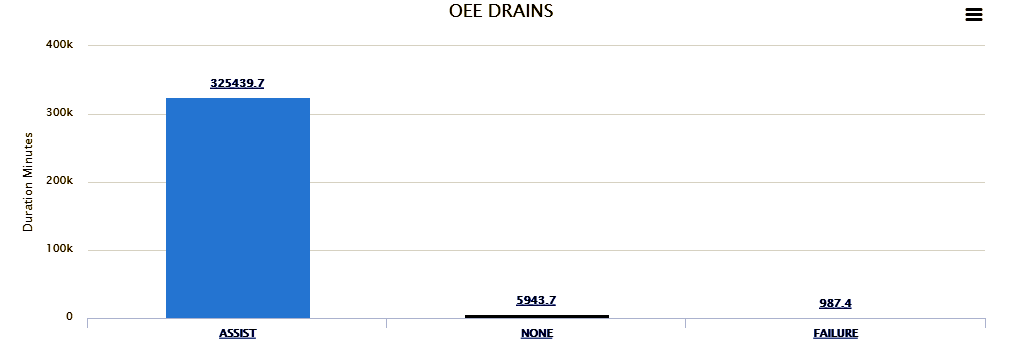

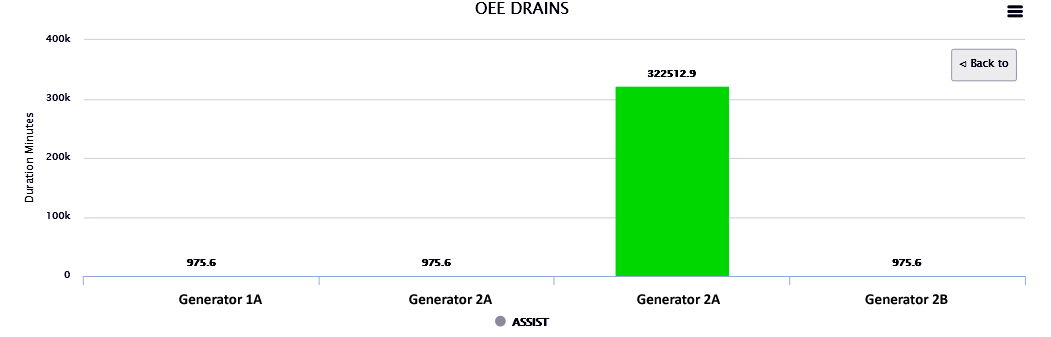

हालांकि, इसका मतलब यह नहीं है कि यह जनरेटर कम उपलब्धता का कारण है, क्योंकि उपरोक्त केवल वर्तमान स्थिति दिखाता है। साथ ही नीचे दिए गए बार ग्राफ से पता चलता है कि डाउनटाइम का मुख्य कारण सहायता घंटों की संख्या के कारण है।

Clicking on the assist bar shows that the building 2 generator 2A contributes to nearly 100% of the assist hours.

.

GEM PRECARE Agents

GEM Precare deploys agents which can talk directly to equipment controllers over a host of different physical interfaces and protocols. The key agent features are listed below:

- Real-time data acquisition. GEM Precare agents collect any equipment vital data in real-time for overall equipment health analysis and trends.

- Any equipment vitals. Whichever is needed to be monitored, including abnormal power supply voltage fluctuations, unusual noise, abnormal vibrations caused by rotating parts, fuel leakages, etc.

- Any connectivity. Equipment vitals may be collected through sensors on GEM Precare agent hardware, from the equipment’s own programmable logic controllers or through a combination of both.

- Low latency. GEM Precare agents run on microprocessors which reside in the same location as the equipment, performing on the spot anomaly detection, complex event processing and other latency-sensitive tasks.

- Automated Actions & Complex Event Processing. GEM Precare Rule Engine allows actions to be automatically executed as a result of one or more conditions met simultaneously by one or more monitored signals.

- Machine learning. GEM Precare agents stream data to the GEM Precare cloud platform, where machine learning models are trained for predictive maintenance.

- Dashboards. The GEM Precare cloud platform compiles and presents comprehensive KPIs in user-friendly dashboards side by side with equipment status, alarms and graphs, as well as comprehensive reports. KPIs include OEE, availability, performance, quality, MTBF and MTBA, with traceability of problem areas.

- Flexible hosting options. GEM Precare can be hosted on your choice of private, public or hybrid cloud.

Conclusions

GEM Precare has a set of powerful data acquisition, analytics, predictive and OEE tools for industrial and commercial power generator. GEM Precare gathers, analyzes and presents critical and actionable data plus key performance indicators (KPIs) before a system, subsystem or component reaches its breaking point. In addition GEM Precare collects important data which can significantly reduce maintenance and repair time, as well as truck rolls. Power generator OEMs and service partners using GEM Precare have a set of powerful tools at their fingertips to minimize OpEx and boost customer satisfaction.

Contact Us